Product Design

Employing the latest CAD systems, our experienced in-house design

team provides us with the capability to meet all your product design

requirements.

In Mold flow we simulate the injection moulding filling process, ensures we get the design right first time. From product design, Mold flow full feasibility review, the use of rapid prototyping and analysis of materials, we can handle everything from concept to reality.

Our team of highly skilled and experienced engineers in our technical center will deliver to you a first class final product.

Mould Manufacturing

Our mould manufacturing unit can manufacture various complex mould in shortest possible lead time.

HIGH SPEED CNC MACHINING ADVANCE PRECISION MACHINING TECHNIQUES.

4+mould makers with 10+ years of experience

DFM

In broadest terms, Design for Manufacturability (DFM) - also known as Design for Manufacturing - is the process of consciously and proactively designing products to optimize all faces of manufacturing, including injection moulding. DFM aligns engineering and production in the initial design phase so potential problems can be identified and resolved before they result in costly rework.

Our experienced mould designers provide a complete analysis on the product's manufacturability. We will verify that your part can be injection moulded as desired before we start manufacturing by using the latest DFM Tools & Mold Flow to save manufacturers time and money by identifying:

- Analysis of product

- Detail check list

- Manufacturing Capability

- Quicker response time

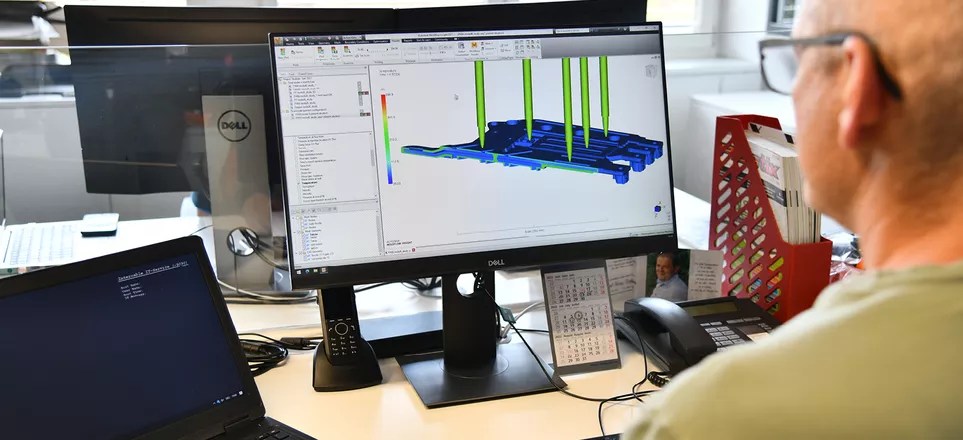

MOLD FLOW

Mold Flow software helps reduce manufacturing defects through plastic injection molding simulation. Access tools for injection mold design, plastic part design, and mold processing.

With our Certified Gold Partner we provide a complete mold flow analysis with all the different aspects of the injection moulding process.

- Runner balancing

- Mould cooling Analysis optimization

- Fiber orientation Analysis

- Gate location Optimization

- Sequence optimization

- Warpage simulation

- Insert Over moulding

MOULD DESIGN

We have expert mould designers with automotive industry, having 10+ years of experience. We continually develop and push the boundaries of tool design.

- 4+ Mould Designers

- Quicker response time

- Ongoing Refinement of Standards

- Cost Effective design

- 3D Motion simulation

Why Sanguine Tech?

Sanguine Tech India offers the best consultancy services that can put an invincible impact on your business performance. Our experts analyze your business demands and requirements and personalized industrial solutions are then delivered. The flexible consultancies as well as delivery of highly responsive products are the attributes that makes us the best receiving gauge manufacturer in NCR. We understand the value of hard earned money; therefore, the products are manufactured and delivered as per industry norms to offer you the higher value products.

We also offer pre sales as well as the post sales assistance for technical and manufacture issues. The products are available in very affordable packages. No compromise is made to the quality and performance parameters and hence, advanced products incorporated with optimized manufacture technology are being offered to the small to large scale clients.

- 4+ Mould Designers

- Quicker response time

- Ongoing Refinement of Standards

- Cost Effective design

- 3D Motion simulation

Aluminum Section customized Tables

Sanguine Tech India is a reputed and well renowned manufacturer of Aluminium Table in Manesar. Apart from this, the company offers Proto Development Parts, Sheet Metal Dies, Receiving Gauge, Pressure Casting Dies, Plastic Moulding Dies, Spare Parts and Sub Assemblies, Jigs and Fixtures, Chutes and Conveyor System, etc. We always try to maintain the fame and recognition by providing high grade industrial supplies to our valued clients. To offer 100% customer satisfaction is our main focus and we leave n stone unturned to achieve our goals.

Custom Aluminium table are available in different specifications for fulfilling varied industrial purposes. The products are provided for small to large scale industries as per client requirements. We hold a large clientele database of happy customers who continue to take our services from a couple of years. We maintain close relationship with our clients from initiation to completion of their orders. Our expert executives visit the site to listen to the client’s specific demands. Measurement is then taken and the product is delivered on the promised date and time.

Personalized Dimension & Specification

Our team of expert professionals put all their efforts to deliver the best Aluminium tables with right dimension and specifications and this is the reason why we are known as reliable manufacturer of Aluminium Table in India. Tables in all sizes and shapes are manufactures using high grade aluminium metal. The products are manufactured keeping durability and reliability parameters in mind. All the products are designed with eye to detail to offer complete satisfaction to the clients. Budget for the product is demonstrated to the respective party before initiating the manufacture process to avoid any sort of inconvenience to the client.

Apart from this, we are also a renowned CNC Turned parts manufacturer based in NCR. These components are manufactured using aluminium, stainless steel, carbon steel and copper alloy. The products being offered by our company provides a high volume repeatability and accuracy. Our experts are integrated with advanced technical as well as mechanical knowledge and skills. The machinery is highly equipped with the innovative and updated technology that delivers high grade stainless steel and metal components.

Flexible Handling of Orders

Customized orders are being executed with the skilled expertise of the expert manufacturing team. Small to large scale orders are accomplished as per client's specific requirements at a very competitive price. The products are manufactured for various industrial purposes and broad application area. A thorough analysis is done over individual business profile and appropriate industrial solutions are offered with eye to detail.

We offer consultation services for all the industrial products being required by the clients. A wide range of products are offered, tailored to specified industrial demands.